Jerry Coffman, K5JC, formerly WB5RUA

Files

Midland XTR&SyntechII Windows Programming ZipFile

Midland 70-0351 XTR Schematic

Midland 70-0351 XTR Manual

Midland 70-1340b XTR Manual

Midland 70-0520cwb Low Band Syntech-II Manual

Midland 70-0520 Low Band Syntech-II Manual

Midland 70-342 Syntech-I Manual

Midland 70-050&70-055 Syntech-I Manual

Midland 70-530b UHF Syntech-I Manual

Motorola Syntor-X9000 Programming ZipFile

Motorola Maxtrac Programming ZipFile

Motorola Radius Programming ZipFile

Motorola Maratrac Programming ZipFile

Note: Rename maratjc.exe to maratrac.exe for Maratrac out-of-band programming

Motorola Maratrac Low Band Manual

Regency Slantface Radio Manual

Aerotron Mega-E Low-Band Manual

Useful Links

Jerry's Ebay Items

Brooke's Ebay Items

Terry's Ebay Items

Repeater Builder's Radio Info

Batlabs's Motorola Radio Info

Converting 2-Crystal PLL-02A CB to 10 Meter AM

Calculate Operating Frequency for Various Radios

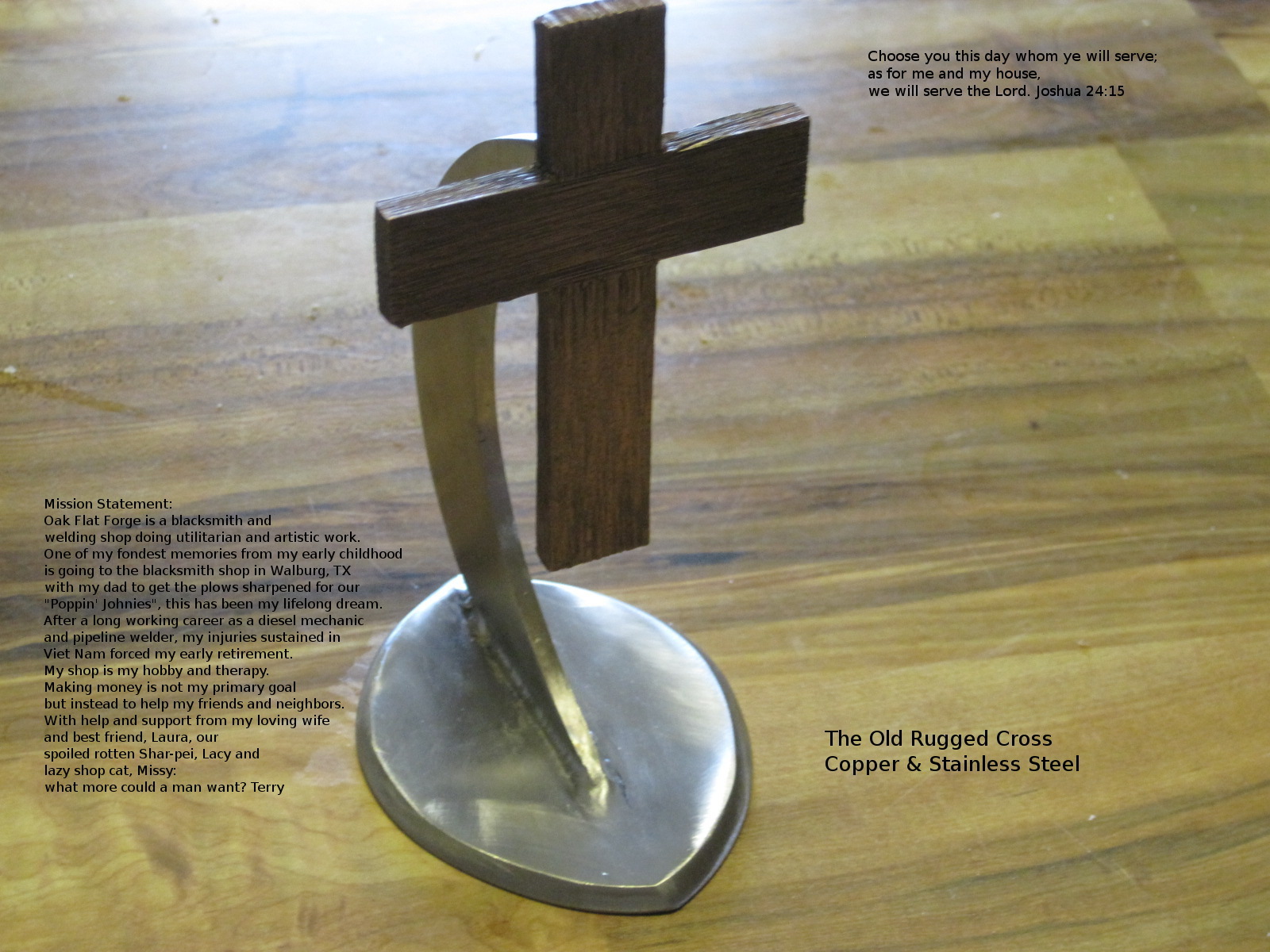

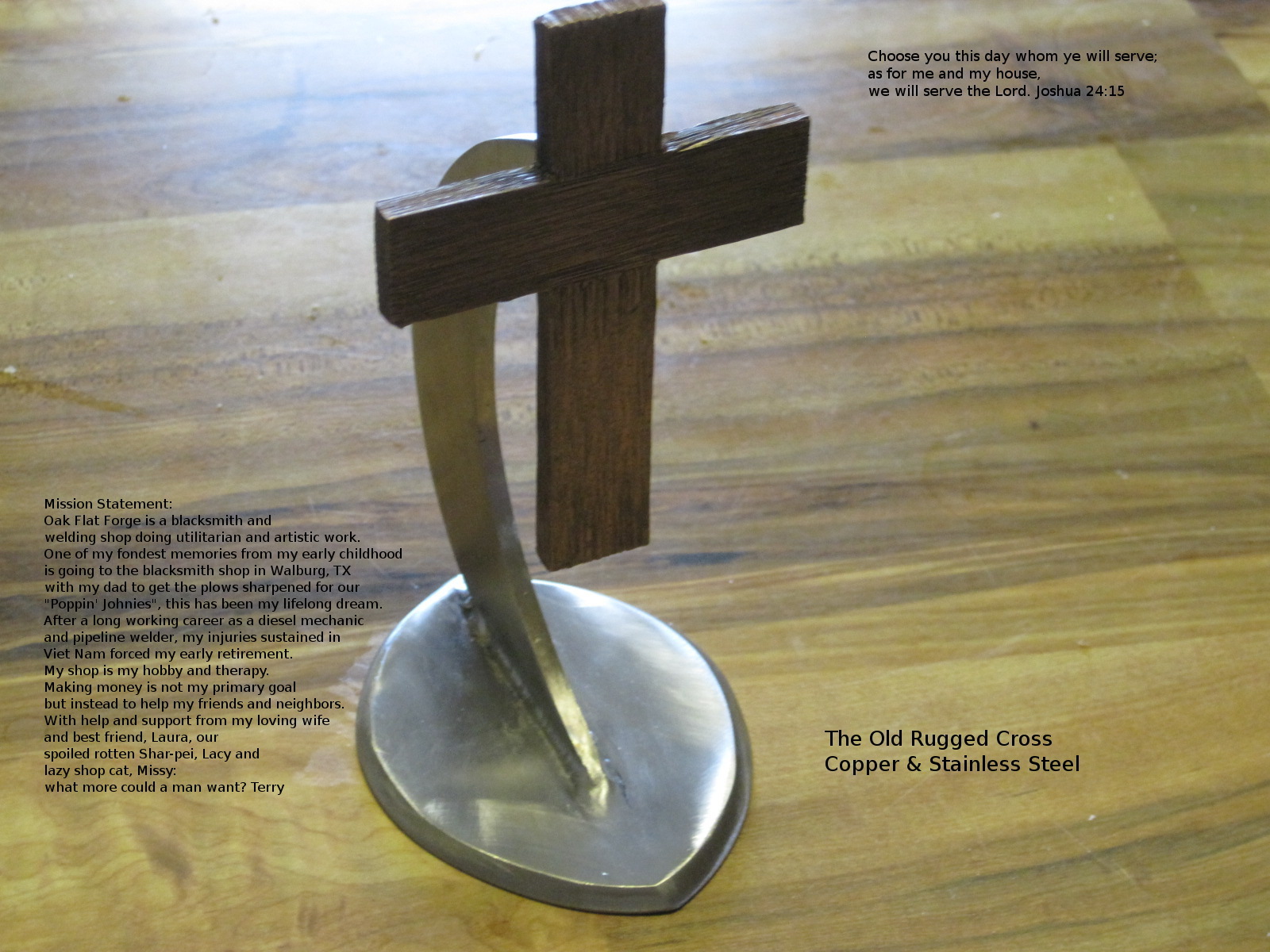

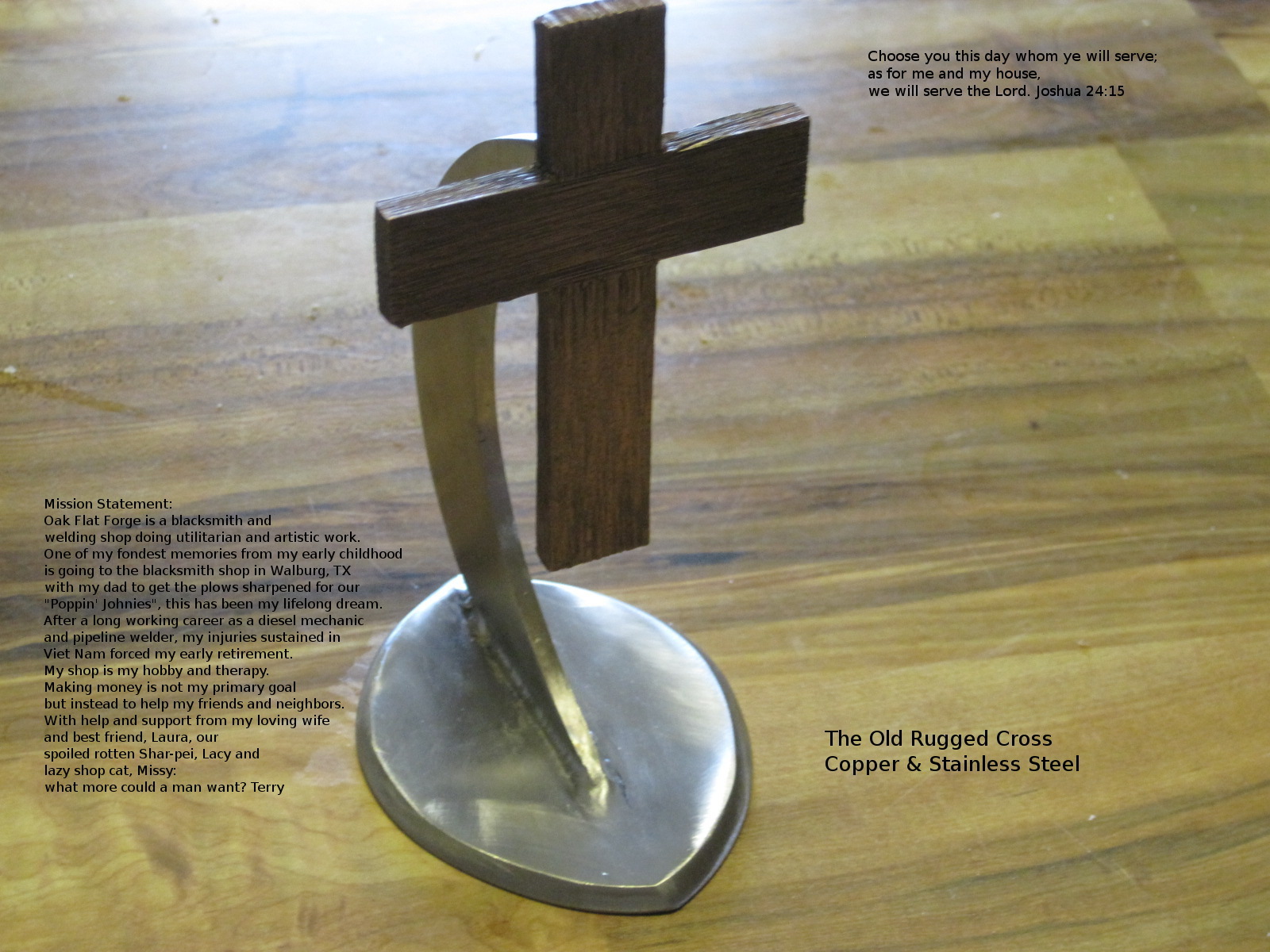

Neat Items Made by

Oak Flat Forge

Terry Coffman

(936) 876-3036